- During plant commissioning:

- Supporting plant commissioning;

- Monitoring temperature, pressure, flow rate, dust, NOx, CO, SO2, O2, CO, CO2, to confirm combustion efficiency of the boiler;

- Analyzing coal, slag and fly ash;

- Investigating the NH3 distribution of SCR system;

- Analyzing absorption solution (slurry) of FGD system.

- Monitoring stack gas.

- Exhaust gas treatment system performance testing services:

- Performance testing for boiler combustion, including air balance test, coal fineness test;

- Performance testing for De-NOx Selective Catalytic Reduction (SCR) system, including AIG Tuning;

- Performance testing for Air Preheater (APH) system;

- Performance testing for Electrostatic Precipitator (ESP) system;

- Performance testing for Flue Gas Desulfurization (FGD) system.

- Performance testing for Mist Eliminator (ME) system.

- Environmental measurement:

- Continuous monitoring: NOx, SO2, CO, CO2, O2 in exhaust gas by gas analyzer;

- Monitoring: temperature, pressure, flow rate, dust, NOx, SO2, SO3, CO, CO2, O2, NH3, HCl, HBr, HF, Cl2, Br2, etc. in exhaust gas;

- Analyzing the quality of wastewater and sludge.

▼ Waste incineration plant

☆ Proposal for Thermal power plant

Optimization of power plants and the improvement in efficiency with operation control and measurement method:

| 1 |

Cost down |

① Improvement of combustion efficiency in boiler

② Energy saving

③ Using ammonia and limestone reasonably |

| 2 |

Improvement in performance of environmental facilities |

① Measurement of catalyst performance and NH3 distribution at De – NOx

② Improvement for dust collection efficiency by optimizing ESP

③ Comprehensive evaluation of De – SOx

④ Maintenance of wastewater treatment system |

| 3 |

Proposal of optimal technologie for measurement and analysis |

① Improvement of measurement and analysis precision

② Improvement of productivity

③ Reduction of environmental impact |

| 4 |

Proposal of operation technologies for a variety of plant |

① Improvement of operation conditions

② Improvement of plant performance |

◆ Investigation and analysis of special contents in flue gas

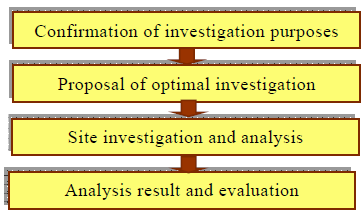

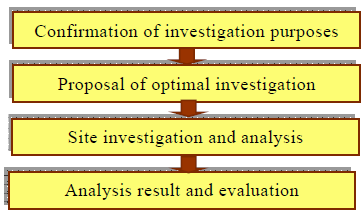

Based on the experiences and achievements gained in the process of exhaust gas monitoring, performance testing, and commissioning at plants, Chugai Technos carries out investigation and analysis to propose optimal methods for sampling and analysing the special ingredients in exhaust gas.

- Investigation of pollutants not included in emissions regulations;

- Investigation of SO3 in exhaust gas,

- Investigation of total dust, particle size;

- Investigation of mist in exhaust gas,

- Investigation of exhaust gas in various plant.

| ▼ Sampling equipment system |

|

| ▼ SCR Performance Test |

|

| ▲ APH Performance Test ▲ FGD Performance Test |