Non-Destructive Testing (NDT)

What is Non-Destructive Testing?

NDT, short for Non-Destructive Testing, refers to a range of testing methods that allow for the evaluation and data collection of materials, systems, or components without altering or damaging the object being tested.

NDT is used to detect defects such as cracks, gas porosity, slag inclusions, delamination, lack of penetration, lack of fusion in welds, metal corrosion assessment, composite material delamination, material hardness measurement, concrete moisture measurement, material thickness measurement, determination of size and location of steel reinforcement in concrete, and more.

Thanks to NDT, timely detection of errors in materials, components, and structures is possible to prevent costly damages, avoid hazardous accidents to human lives, property damage, and environmental harm.

Reasons for Using NDT

Here are the primary reasons why NDT is widely adopted by many companies worldwide:

Cost-effectiveness: The most evident answer to this question is that NDT is more appealing than destructive testing because it allows the tested material or object to be preserved during the testing process without any damage, thus saving money and resources.

Safety: NDT is also attractive because almost all NDT techniques (except for radiographic testing) are non-hazardous to humans.

Efficiency: NDT methods allow for a thorough and relatively rapid evaluation of materials, which can be crucial in ensuring continuous safety and performance on the field.

Accuracy: NDT methods have been proven to be accurate and predictable, both qualities desired when it comes to maintenance procedures to ensure human safety and equipment longevity.

Non-Destructive Testing Methods

Visual Testing (VT)

Visual Testing (VT), also known as visual inspection, is one of the most common techniques involving the operator visually examining the test sample. Visual testing may be aided by optical instruments such as magnifying glasses, microscopes, or automated optical measuring systems.

This method allows for the detection of corrosion, misalignment, damage, cracks, dimensional deviations, etc. Visual testing is inherent in most other NDT types as they often require the operator to identify and evaluate defects before proceeding with other testing steps. In fact, the various shortcomings of visual inspection have made other NDT methods necessary.

Ultrasonic Testing (UT, PAUT)

Ultrasonic Testing (UT) is a group of non-destructive testing (NDT) techniques that use high-frequency, short ultrasonic waves to detect flaws in materials. The method works by sending waves into a material. By measuring these waves, the properties of the material and internal defects can be identified.

UT equipment includes pulse generators, receivers, transducers, and display screens. Users require a certain level of experience when using ultrasonic equipment. Simple ultrasonic techniques can assist users in measuring material thickness, detecting defects, and testing welds with appropriate transducers.

Additionally, there are more advanced ultrasonic testing techniques:

Phased Array Ultrasonic Testing (PAUT) is a technique using an array of ultrasonic transducers composed of multiple small elements. Each element in the PAUT system can emit individual pulses. This is done with timing calculated by a computer, through a process called phasing. It allows the system to steer the beam through multiple angles and focal distances.

Like all NDT methods, ultrasonic testing is not perfect for every application. Materials with coarse grain structures impede the wave transmission process. Non-standard shapes, including curved surfaces, can sometimes pose difficulties in contact and lack standardized techniques or complete solutions. Additionally, the quality of the transducer significantly affects penetration depth and image quality during ultrasonic testing.

Magnetic Particle Testing (MT)

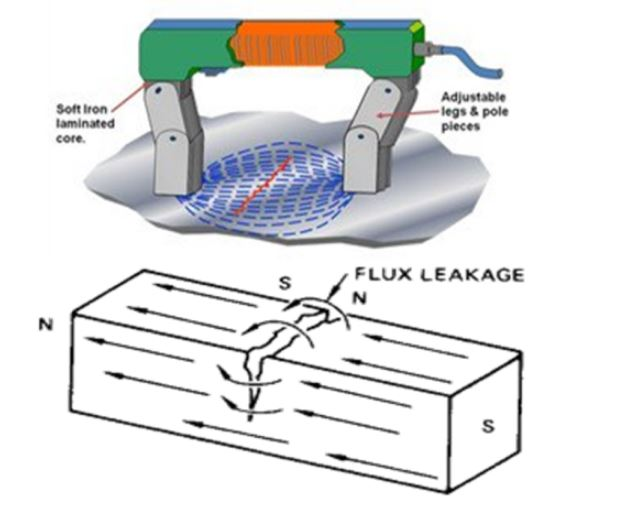

Magnetic Particle Testing (MT) is used to detect surface and near-surface flaws in most ferromagnetic materials such as iron, nickel, and cobalt, and some of their alloys. Because it doesn’t require surface preparation as demanded by other NDT methods, carrying out MT is relatively quick and straightforward. This has made it one of the widely used NDT techniques.

To perform Magnetic Particle Testing, the inspector first generates a magnetic field in the material that is easily magnetized. After creating the magnetic field, the surface of the material is covered with fine iron particles, and the arrangement of these particles indicates discontinuities or continuity of magnetic flux lines. These discontinuities provide visual indications for locations of imperfections in the material.

Liquid Penetrant Testing (PT)

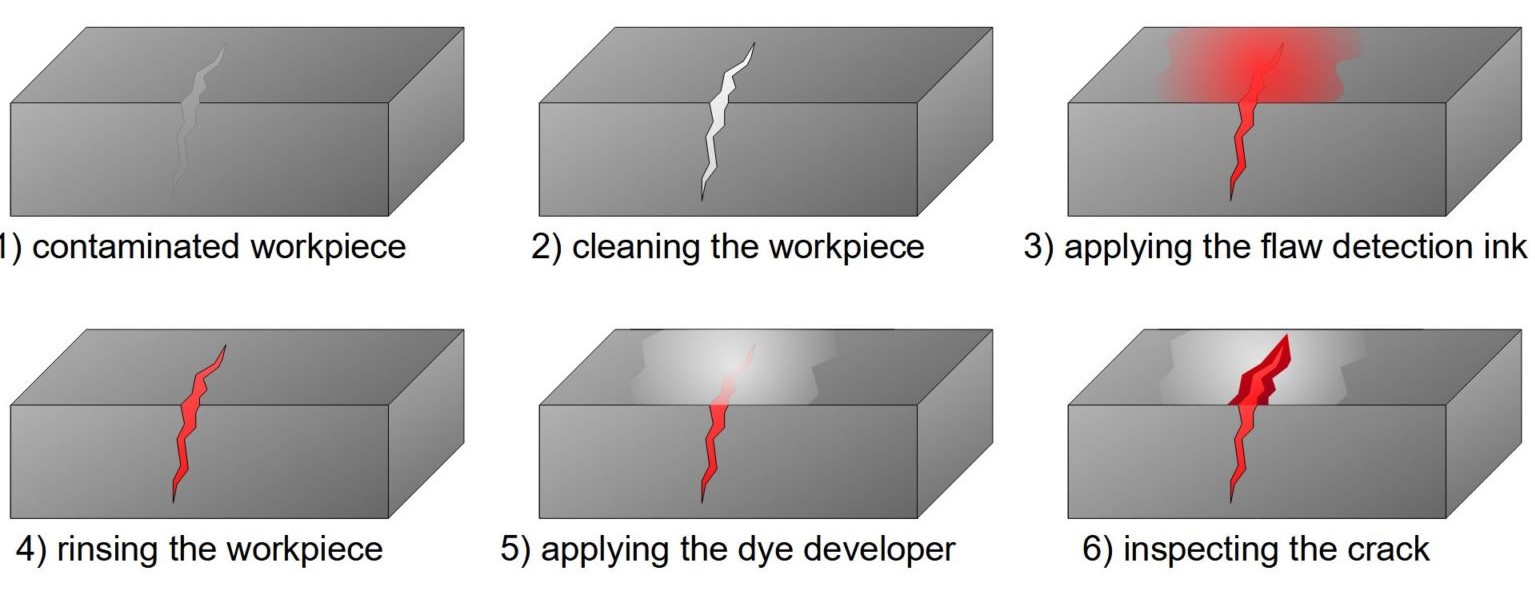

Liquid Penetrant Testing (PT) is a non-destructive testing (NDT) technique that uses fluorescent dye penetrants to detect surface flaws on parts and equipment that may not be visible. This technique operates on the principle of “capillary action,” a process where the liquid flows into a narrow space (μm) without the assistance of gravity.

As one of the easiest and least costly NDT techniques to perform, PT is one of the most widely used testing techniques in many industries, including the oil and gas sector.

Although this method is effective due to its simplicity and accuracy, it also has its drawbacks. If defects do not have open openings on the surface, the liquid cannot penetrate. Therefore, other methods must be used to detect defects not located on the surface or when the material is impermeable. The surface of the material must also be clean as oils and other residues can hinder the penetrant’s ability to seep into the crack. Additionally, penetrants require equipment and cleaning processes as well as chemical handling. While this technique can be effectively utilized, it is also slower and more cumbersome than other NDT methods.

Eddy Current Testing (ECT)

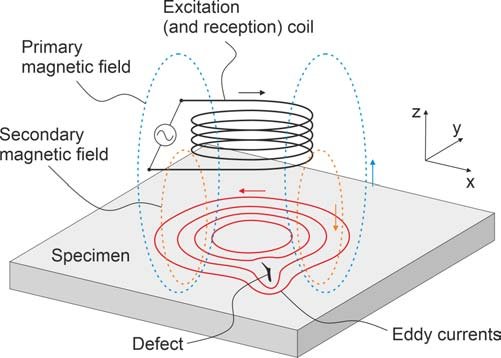

Eddy Current Testing (ET) is a technique used to detect flaws or corrosion in ferrous materials. It can also measure the thickness of the aforementioned materials.

This technique operates by applying a voltage to an eddy current probe. The coil generates a changing magnetic field using alternating current, after this magnetic field interacts with the test sample, eddy currents are generated.

Variations in phase and magnitude of these eddy currents are monitored either by using a second coil or by measuring changes in the current flowing through a coil. The presence of any flaws will cause a change in the eddy current field and a corresponding change in the phase and amplitude of the measured signal.

This method can also be used on non-conductive materials.

Radiographic Testing (RT)

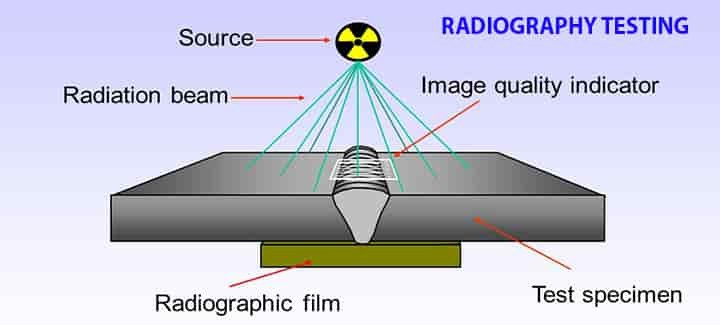

Radiographic Testing (RT) is a non-destructive testing (NDT) method that uses X-rays or gamma rays to inspect the internal structure of manufactured components to identify any defects or flaws.

In radiographic testing, the test piece is placed between the radiation source and the film (or detector). Differences in density and material thickness of the test component will attenuate the radiation through processes involving scattering and absorption. Differences in absorption are then recorded on the film(s) or via integrated computer.

In industrial radiography, there are several imaging methods available, techniques to display the final image, such as Film Radiography (2D), Real-Time Radiography (RTR), Computed Tomography (CT), Digital Radiography (DR), and Computed Radiography (CR).

Leak Testing (LT)

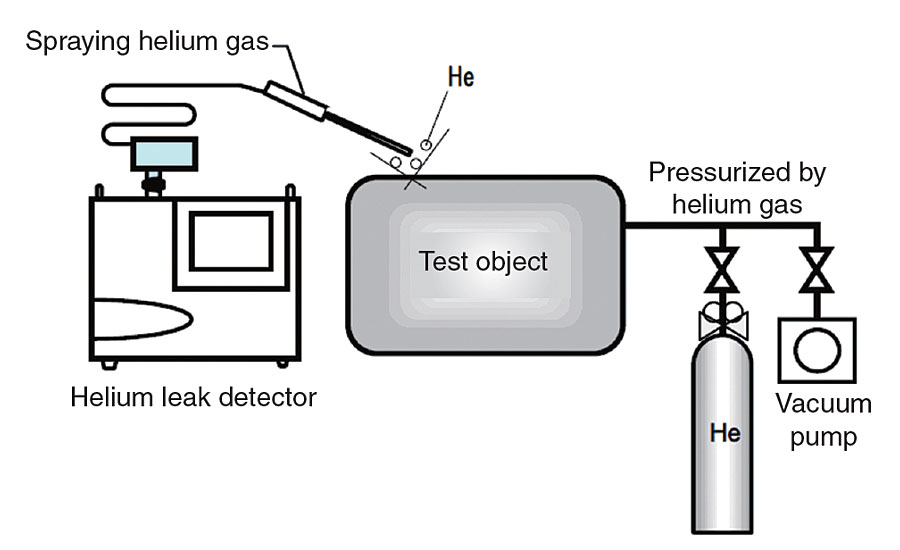

Leak Testing (LT) is a non-destructive testing (NDT) method that refers to the process of investigating leakage in a container or structure to identify the defects causing leakage.

Inspectors can detect leaks inside the vessel using measurements performed with pressure gauges, bubble soap tests, or electronic listening devices.

Halogen diode and mass spectrometer testing, both use gas identification to detect the presence of leaks. Halogen or helium (often mixed with air) is introduced into the pressurized vessel. A halogen diode detector or mass spectrometer placed outside the pressurized area will alert technicians to the presence of halogen or helium, indicating a leak.

Some bubble testing can be performed on-site, with specialized equipment to create sealed areas on large, flat surfaces. However, bubble testing and other leak testing methods are time-consuming and require cumbersome equipment and setups.