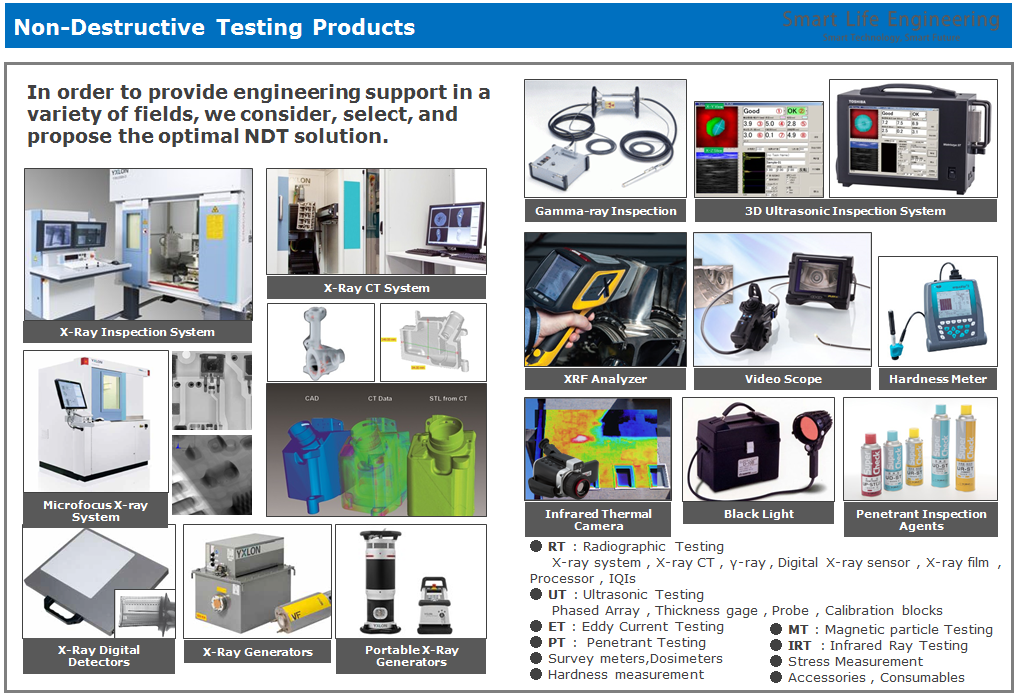

Olympus is committed to providing the very best technical support for your remote visual inspection and non-destructive testing (NDT) equipment, and XRF/XRD analyzers including thickness gages, flaw detectors, industrial scanners, inspection systems, industrial microscopes, probes and transducers.

I. Thickness Gage

OLYMPUS is the leading source of thickness gages for the accurate measurement of nearly all materials. Thickness gages include a wide range of features available for enhanced gage performance. Ultrasonic thickness gages can measure virtually most materials such as plastics, metals, metal composites, rubber and internally corroded materials.

1. Model 27MG

|

The 27MG is a basic ultrasonic thickness gage designed to make accurate measurements from one side on internally corroded or eroded metal pipes and other parts. It is lightweight, durable, and ergonomically designed for easy, one-hand operation.

|

2. Model 45MG

|

The 45MG is an ultrasonic thickness gage packed with standard measurement features and advanced software options such as live A-scan with waveform adjust, Echo-to-Echo/THRU-COAT, single element transducers use, high solusion. It can measure virtually most materials such as plastics, metals, metal composites, rubber and internally corroded materials.

|

3. Model 38DL Plus

|

The 38DL Plus is an ultrasonic thickness gage packed with standard measurement features such as live A-scan with waveform adjust, Echo-to-Echo/THRU-COAT, external oxide / scale layer through measurement and advanced software options such as single element transducers use, internal Oxide/Scale thickness measurement, Encoded B-Scan. It can measure virtually most materials such as plastics, metals, metal composites, rubber and internally corroded materials.

|

4. Model Magna-Mike 8600

|

The Magna-Mike is a Hall Effect thickness gage that uses a magnetic probe to perform accurate measurements on nonferrous and thin materials such as plastic và glass bottles.

|

II. Flaw detectors (Ultrasonic and Phased Array)

We has an extensive portfolio of ultrasonic flaw detectors that offer capability for applications ranging from welds and casts inspections to the detection of cracks, porosity and other internal irregularities in metal, composite materials. Our high quality flaw detectors offer numerous practical measurement features, application specific software, ease-of-use, versatility, and ruggedness.

1. Model Epoch 600

The Epoch 600 is mid-level handheld ultrasonic flaw detector, weighing only 1.68 kg (including lithium-ion battery), it case is built to withstand the rigors of very harsh environments. EN12668-1 plus features such as 400V PerfectSquare tunable square wave pulser, digital filtering for enhanced signal-to-noise ratio, the high efficiency of a portable and intuitive instrument. The Epoch 600 flaw detector blend of efficient menus and direct access keys allows you to ease of use.  |

2. Model Epoch 650

|

The Epoch 650 is a new ultrasonic flaw detector with preeminent inspection performance and usability for a wide variety of applications. This is a continuation of the popular EPOCH 600 flaw detector with additional capabilities such as full screen A-Scan mode, up to 37 filter, capture screen shots and video recording feature to report. Corrosion testing with accuracy up to ±1%.

|

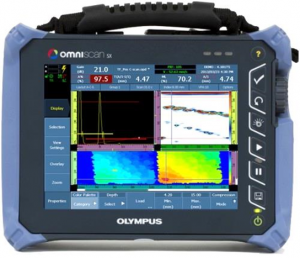

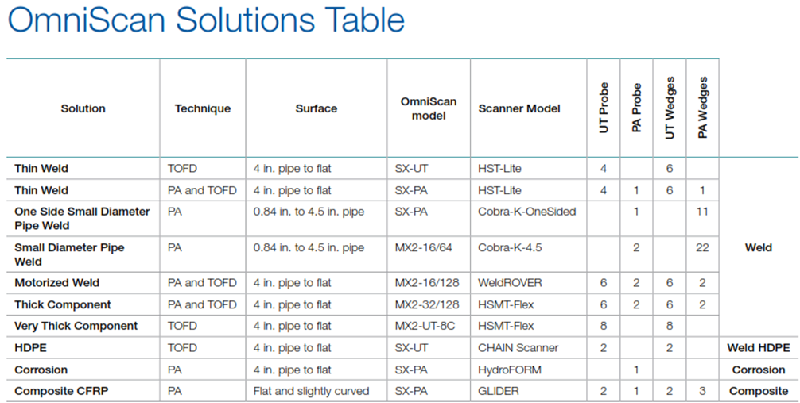

3. Model OmniScan SX

|

The OmniScan SX is a flaw detector color 3D phased array technology with display A-Scan, B-Scan, C-Scan, S-Scan and it’s the manual and semiautomated inspection solutions. OmniScan SX is ideal for corrosion mapping or weld or pipe-to-component inspection solutions using a probe Phased Array and TOFD channel on the metal or composite materials. |

4. Model OmniScan MX2

|

The OmniScan MX2 is a advance flaw detector color 3D phased array technology with display A-Scan, B-Scan, C-Scan, S-Scan and it’s the manual or semiautomated or automated inspection solutions, designed for modules compatibility. OmniScan MX2 is ideal for corrosion mapping or weld or pipe-to-component inspection solutions using two probe Phased Array and TOFD channel on the metal or composite materials.

|

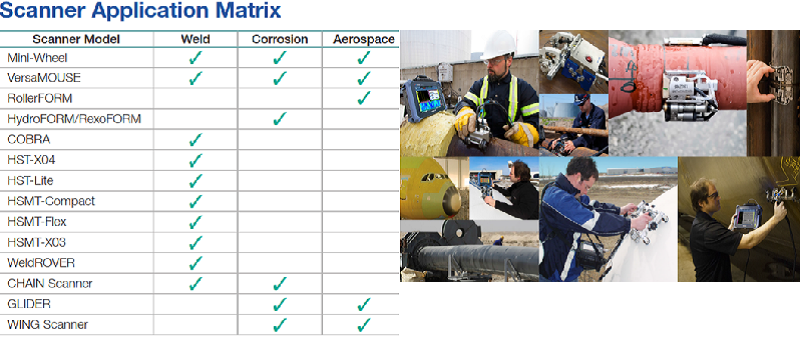

5. The Scanners for OmniScan

We has are extensive portfolio of the scanners for OmniScan that offer capability for applications ranging from the 2-axis XY enconded for corrosion mapping inspection (motorized and manual), welds pipe with 0.84 inch outside diameter (OD) up to flat inspection (motorized and manual). This scanners provide reliable, accurate performance in a wide range of heavy duty industrial applications.

III. Handheld XRF Analyzers

DELTA Series Handheld XRF Analyzers provide fast, non-destructive testing method to elementals analysis from Mg to U, from ppm to 100%. Being used for immediate analysis results, they help determine the next course of action, when and where it’s needed. DELTA Series is a ideal for applicationsas follows:

1. Scrap Sorting and Recycling Analysis

Provides reliable identification in 1-2 seconds for most alloy grades and pure metals. It is designed for durability to withstand the toughest environments. It is ideal for checking a wide variety of materials including ferrous and nonferrous metals, glass, and plastics in seconds.

2. Alloy Positive Material Inspection (PMI)

Analytical and positive material inspection (PMI) analyzer is vital for quality control and assurance in the metal manufacturing and fabrication industries. It is used for compositional analysis and alloy grade identifi cation.

3. Consumer Safety and RoHS Analysis

The DELTA screens for pollutants and poisons such as lead, cadmium, chromium, mercury, arsenic and other toxic elements. It is used to help ensure safety and to help comply with global regulatory programs directed by EPA, RoHS/WEEE, CPSC, FDA, and more…

4. Jewelry-Precious Metals Identification

Provides fast, accurate alloys chemistry and karat classification by one nondestructive test method. Whether importing precious metals, selling or producing jewelry, or processing scrap metal, the DELTA Series is the ideal choice.

5. Geochemestry and Mining Exploration

The DELTA Series is the ideal choice for detection of metals, minerals and contaminants in the soil, rock,chip and sediment…

IV. Industrial Videoscopes

1. Model: IPLEX TX

The IPLEX TX is a videoscope with ultra-thin 2.4 mm diameter and 1.2 m length scope tube, it’s enables you to make inspections inside parts where access is limited due to very narrow opening and it’s to clear images. The IPLEX TX is the ideal videoscope for routine inspections of castings, molds and other parts with small cavities.

The features: Visual, image and video recording.

2. Model: Series C

The Series C is a videoscope with 6.2 mm diameter and 2 m length scope tube, It’s provides durability and great optics to get you the image you need. The instrument is built for use anywhere you need it and packed with features usually reserved for more expensive units of Olympus. The Series C will save you very time and money.

The features: Visual, image and video recording.

3. Model: IPLEX UltraLite

The palm-sized IPLEX Ultralite industrial videoscope, weighing just 700 g, designed with 4 mm or 6 mm diameter and 2 m or 3.5 m length scope tube, delivers high quality images. Its compact, durable body enables inspections in tough and confined areas.

The features: Visual, image and video recording, stereo measurement.

4. Model: IPLEX RX/RT

The IPLEX RX/IPLEX RT are industrial videoscopes that features to the best quality images. The technology our unique PulsarPic™ image processor reduces noise and sharpened images, resulting in the exceptionally high resolution image, that very good to inspections at metal stainless steel or high reflective surfaces. It has a large 6.5 inch screen with an anti-reflective daylight-view monitor, 4 mm or 6 mm diameter and 2 m or 3.5 m or 5 m or 7.5 m length scope tube. The IPLEX RX and RT to provide faithfully and brightly images, very good to detected very small defects, the sharp and clear images enable accurate and reliable inspections.

The features: Visual, image and video recording, stereo measurement (Only IPLEX RX).

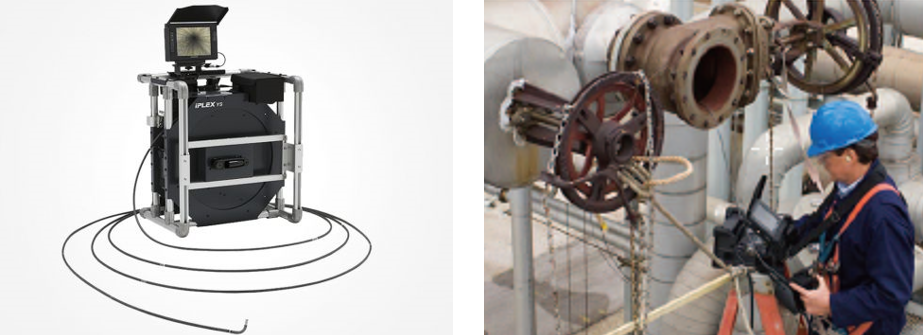

5. Model: IPLEX FX

The IPLEX FX is a high-end industrial videoscope system combining portability with advanced functionality, and ease of use with high durability, from high image quality inspection to retrieval operation, built to withstand the rigors of very harsh environments. The scopes tube unit may be interchangeable, therefore it to allowing you to choose scopes tube unit many fit the each job such as 4 mm or 6 mm diameter and 2 m or 3.5 m or 5 m or 7.5 m or 12 m or 18 m length scope tube. The WORKING IPLEX FX allow you to remove foreign objects from inside inspection areas, ideal for helping avoid costly overhauls, perform to hook and drag jobs.

The features: Visual, Audio and image and video recording, stereo measurement.

6. Model: IPLEX YS

The IPLEX YS is a industrial videoscope ideal for inspecting long reach areas such as heat exchangers, boiler tubes and water feed pipes. Accurate visual inspections for hard-to-reach areas up to 30 m deep are now easier than ever. It delivers unprecedented image quality and maneuverability.

The features: Visual, Audio and image and video recording, stereo measurement.

V. Advanced Equipment

1. Model: MultiScan MS5800

It’s a multi-technology system that offers eddy current (ECT), magnetic flux leakage (MFL), remote field (RFT), near field (NFT), and ultrasonic Internal Rotating (IRIS) inspectin solution. The MultiScan MS580 is used inspection to dectects the corrosions, erosions, pittings, cracks defects at internal and external surface for tubes of condensers, feedwater heaters, air conditioners, boilers and air coolers…

2. Model: UltraWave LRT

The UltraWave LRT used guided wave technology and excites low-frequency ultrasonic waves that travel lengthwise over tens of meters along a conventional structure and buried, insulated, coated, and vertical pipings to detecting wall thickness variations (corrsions). It pinpoints locations that require further inspection, avoiding unnecessary excavation, coating removal, or scaffolding. The use of this technology helps provide a significant reduction in operating cost.

1. Ultraviolet Inspection Lamps

It is a general-purpose type of ultraviolet inspection lamps. By adopting the LED to the ultraviolet lamp, it is possible to instantly light but the lamp does not become hot. In addition, small, lightweight, lamp life has become about 20 times compared with conventional product.

- LED type: Super Light D-10L

- Metal halide lamp type: Super Light D-10B

2. Penetrant testing agent

– Metallic materials: defect found on surface of the rolled product, forging, casting, weld, etc

– Non-metallic materials: defect found on the surface of the ceramic, glass, plastic, etc