Flue Gas Desulfurization (FGD) System Performance Test:

- Receiving the trust of MHI Solution Technologies (MHI Soltec) – Manufacturer of SWFGD system, Chugai Technos conducted the pre-performance test of SWFGD system for unit 1 and unit 2 with the following items:

- Measurement and analysis of exhaust gas at FGD inlet and outlet, bypass and stack;

- The monitoring equipment system complies with Japan JIS standards, meeting the characteristics of the sampling location (horizontal duct, depth of 7m at the outlet of the FGD system);

- Measurement parameters: temperature, pressure, velocity, flow rate, moisture content, gas composition (O2, CO2, and N2), SO2 concentration; dust concentration.

- Report content:

- The basic exhaust gas parameters (including: temperature, pressure, velocity, flow rate, moisture content, gas composition);

- SO2 concentration;

- SO3 concentration;

- Dust concentration;

- Desulfurization efficiency;

- SO2 concentration distribution; dust concentration;

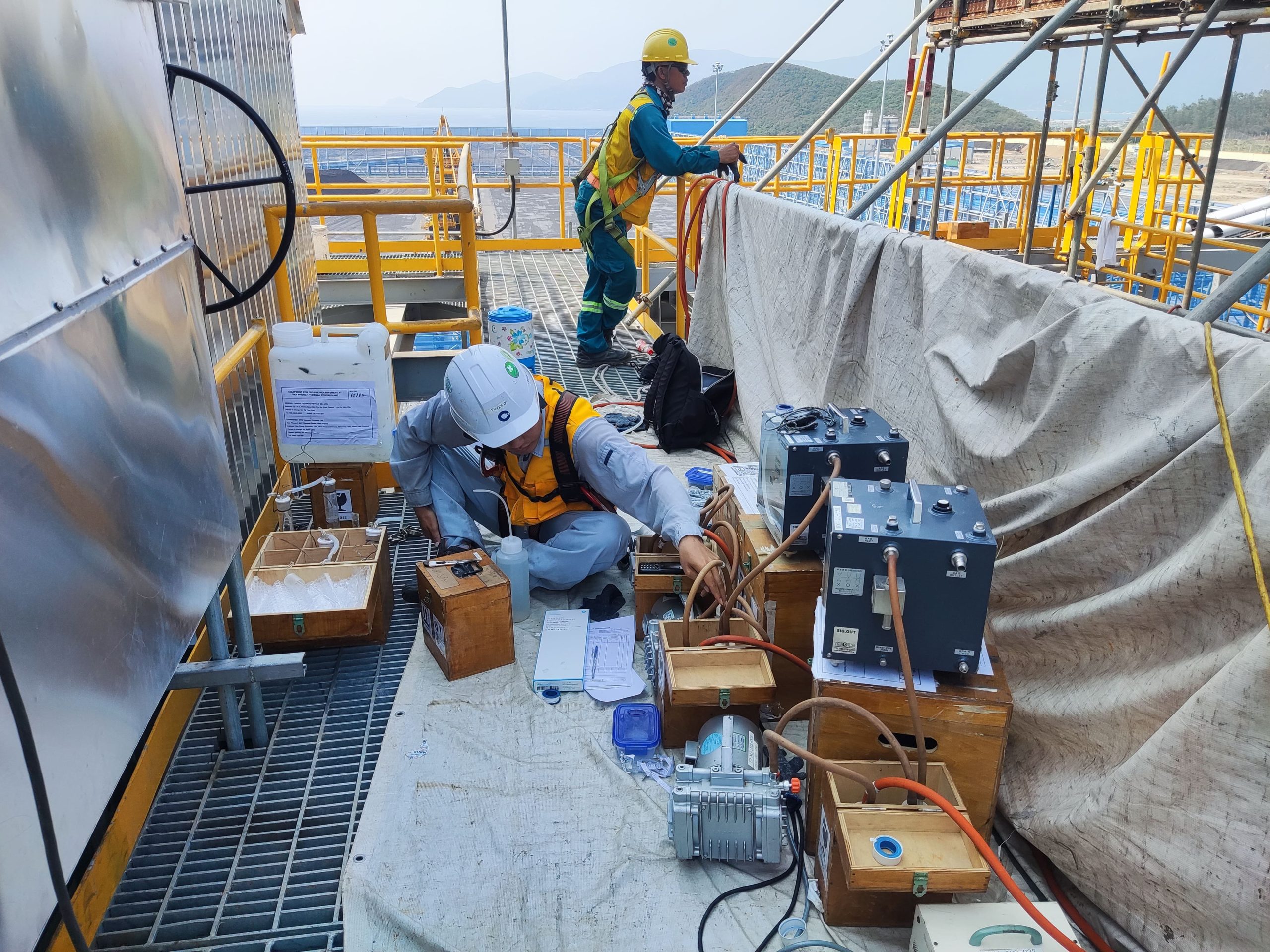

- Chugai Technos team of engineers performed the work in night operating conditions according to the operating schedule of Van Phong 1 Thermal Power Plant with difficult working conditions. Accompanying experienced engineers who are leading Japanese industry experts and Indian engineers, Chugai Technos has made good use of its resource advantages to work with customers to build the most optimal solution, meet the actual situation, support FGD producer to operate the system in the most optimal conditions.

The scaffold system supports sampling at the FGD outlet.

7 meters heating sampling tube

SO2 sampling

SO2 sampling at FGD outlet

SO2 sampling control

Monitoring of exhaust gas temperature and pressure

Moisture content sampling – Determination of gas composition

Dust sampling

Dust sample collection

Gather equipment after completing the project