Combustion Tuning Test – Boiler Performance Test:

- Receiving the trust of the contractor IHI Inspection & Instrumentation (ICC), Chugai Technos has conducted the combustion tuning test for the boiler and auxiliary systems during the commissioning period of unit 1 and unit 2, including:

- Air balance test;

- Coal fineness test;

- Combustion tuning test;

- Boiler perfomance test.

- Scope of Work:

- Measuring air flow at coal injection pipes;

- Continuous monitoring of temperature; NOx-CO-CO2-O2 concentration at the outlet of the economizer and inlet of the air preheater;

- Monitoring and analyzing exhaust gas quality at the outlet of the economizer and inlet of the air preheater;

- Sampling and analyzing the quality of injected coal;

- Sampling and analyzing bottom ash quality;

- Sampling and analyzing fly ash quality;

- Use of a simple and easily assembled equipment system to meet the specific requirements of the sampling location (horizontal pipes, off-floor sampling holes, depths up to 6m);

- Monitoring and analysis parameters:

- Exhaust gas: temperature, pressure, velocity, flow rate, moisture content, gas composition (O2, CO2, and N2), dust concentration; NOx-SO2-CO-CO2-O2 concentration;

- Coal fineness: particle size, unburned carbon (UBC);

- Bottom ash: unburned carbon (UBC).

- Report content:

- Basic exhaust gas parameters (including temperature, pressure, velocity, flow rate, humidity, gas composition);

- NOx-CO-CO2-O2 concentrations;

- Dust concentration;

- Distribution of temperature, velocity, dust concentration; NOx-CO-CO2-O2 concentration;

- Analysis results of coal, fly ash, bottom ash;

- Chugai Technos’ team of engineers performed the work in night operating conditions according to the operating schedule of Van Phong 1 Thermal Power Plant with difficult working conditions. Accompanying experienced engineers who are leading Japanese industry experts and Indian engineers, Chugai Technos has made good use of its resource advantages to work with customers to build the most optimal solution, meet the actual situation, contributing significantly to bringing the project to completion on time.

Continuous monitoring of exhaust gas temperature

Coal sampling at the coal pipes

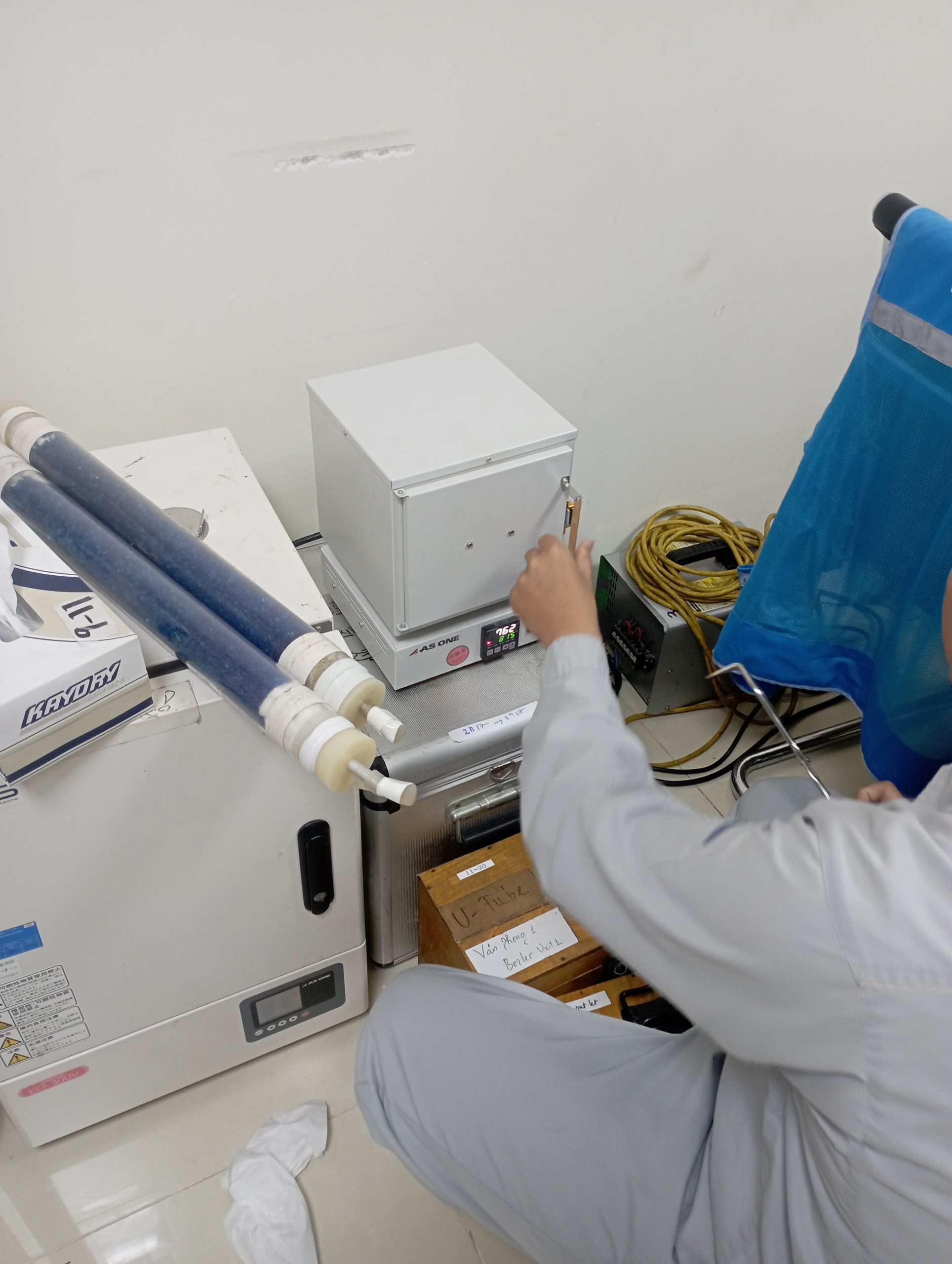

Coal sampling equipment

On-site sample analysis

Measuring flow rate at the inlet of the Air Preheater

Measuring flow rate at the outlet of the Economizer

Determination of gas composition

Fly ash sampling

The equipment is neatly packed up at the end of each measurement day